A Typical Watch Restoration at RomanDial's Workshop.

- David Panunzio

- Nov 17, 2017

- 2 min read

We regularly get asked by our customers what is involved in the restoration process. We have therefore put together a short description illustrated with pictures of the renovation stages.

1. Before Restoration.

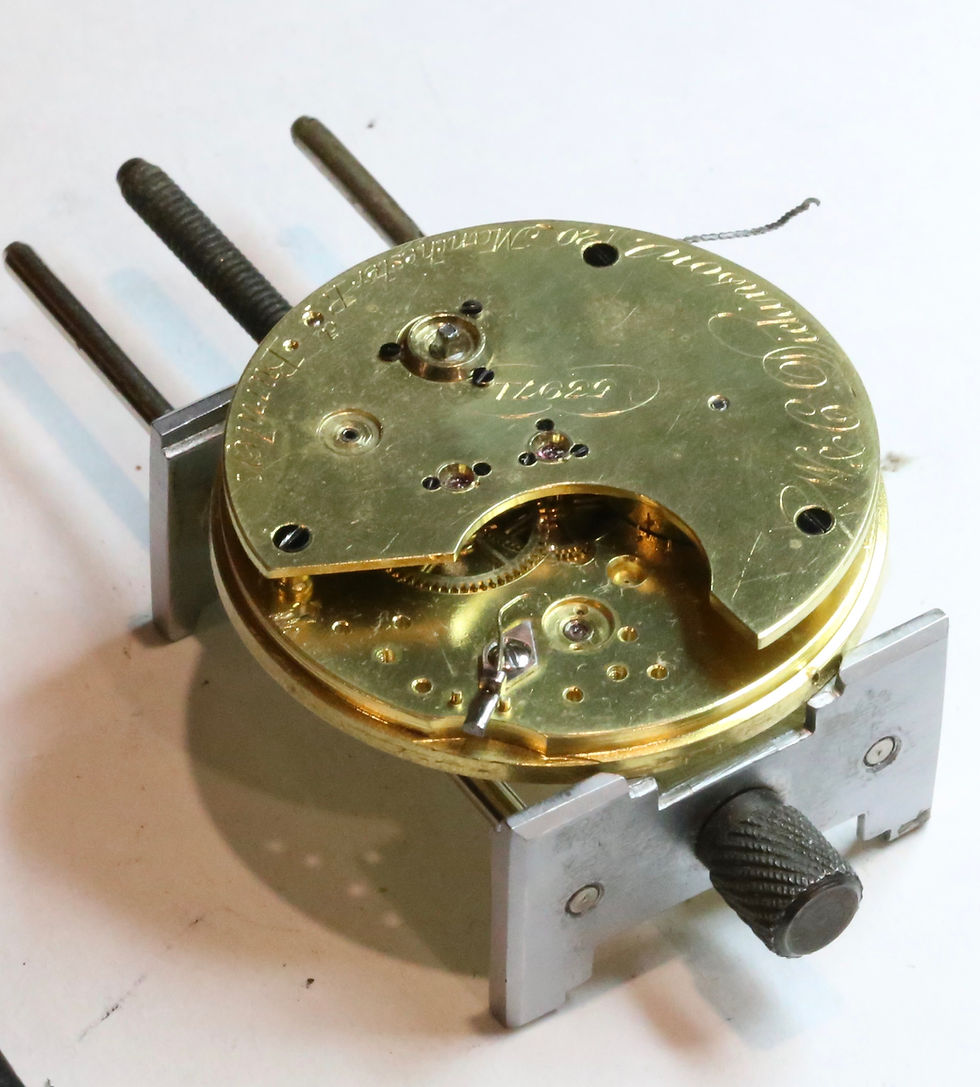

Here we have a chronograph pocket watch from 1886 with an 11 jewel 3/4 plate movement ready to be restored to its former stylish simplicity.

2. Removal of Movement.

To begin with, the hands are removed from the watch and the movement is removed from the case. We won't reuse the hands in this case as the design of the hour and the minute hand are not matching and the second hand is a little short.

3. Service Begins.

We remove the balance first as it is delicate and can be easily damaged.

Once the balance is removed it's cleaned with a solution to clean away dirt grease and oil. This is a specific solution for balances that doesn't dissolve shellac.

Dial has been removed and put to one side for cleaning later. lso you will notice the dial centre had been taped on. It is common for dial adhesives to break down over time but taping it is not a good solution as the tape can interfere with the motion works and also it will peel away.

Motion works are removed and mainspring let down. Parts go into a basket ready for cleaning.

The escapement is removed and placed in the basket. Top plate is removed, the fusee cone is dismantled, spring removed from the barrel and all the parts are put in a cleaning solution and then rinsed.

The parts are left to dry.

Once dry, the reassembly begins.

Top plate is back on..

Fusee chain reattached and escapement back in place.

Balance back in, the stop lever is checked for correct depthing.

.

4. Dial Repair.

Dial is cleaned and traces of tape and adhesive are removed.

All clean, the inner dial and outer dial are lined up.

Adhesive added to the channel.

While the adhesive dries, the motion works are put back in place.

5. Testing & Regulating.

The watch is now ready for testing. It will be run for about a week, regulating it daily

until it is within 1-2 minutes of error per 24h. We always test pendent up as this is the most likely position the watch will be used.

6. Metal Work.

Now the regulating and testing have been completed the case requires attention. Dents and deep scratches are removed then the case is machine polished followed by final hand polishing.

A new glass is fitted.

7. The Finished Product.

The movement is returned to the cleaned and polished case and then pinned.

Written by David Panunzio @romandial.com

November, 2017.

Before I retired in 2016, I purchased a good number of watches from you. They continually give me pleasure. However, some have slowed or don't even run. Still, they are much too valuable to be carried about. Perhaps someday I'll inquire about having some reserviced.

I have brought 3 pocket watches from you and I am completely satisfied with them. They are like new, the restoration is done to a very high standard. Excellent.

Very interesting and informative description of the service procedure. Inspires confidence in your merchandise.